BRIEF: EXPERIMENT WITH APPLICATIONS OF 3D-CONCRETE-PRINTING.

APPROACH: juxtapose concrete with antithetical FORMAL qualities (e.g. lightness, softness, dynamism, comfort, fluidity, and instability) that are only possible with additive manufacturing

OUTCOME: CONCRETE 3D-Printed chair comprised of four tangentially adjoined planes that evoke a feeling of lightness as they appear to be suspended in space.

STATUS: SUSPENDED DUE TO COVID-19

FOCUS: EXPERIMENTATION, DIGITAL MANUFACTURING, MATERIALITY

FOCUS: EXPERIMENTATION, DIGITAL MANUFACTURING, MATERIALITY

THIS PROJECT WAS DONE WHILE AT CARLETON UNIVERSITY'S SENSORY ARCHITECTURE AND LIMINAL TECHNOLOGY LAB in the Azrieli School of Architecture, WHERE I worked with a small group of architects, engineers, and machinists to develop a large format concrete 3D printer.

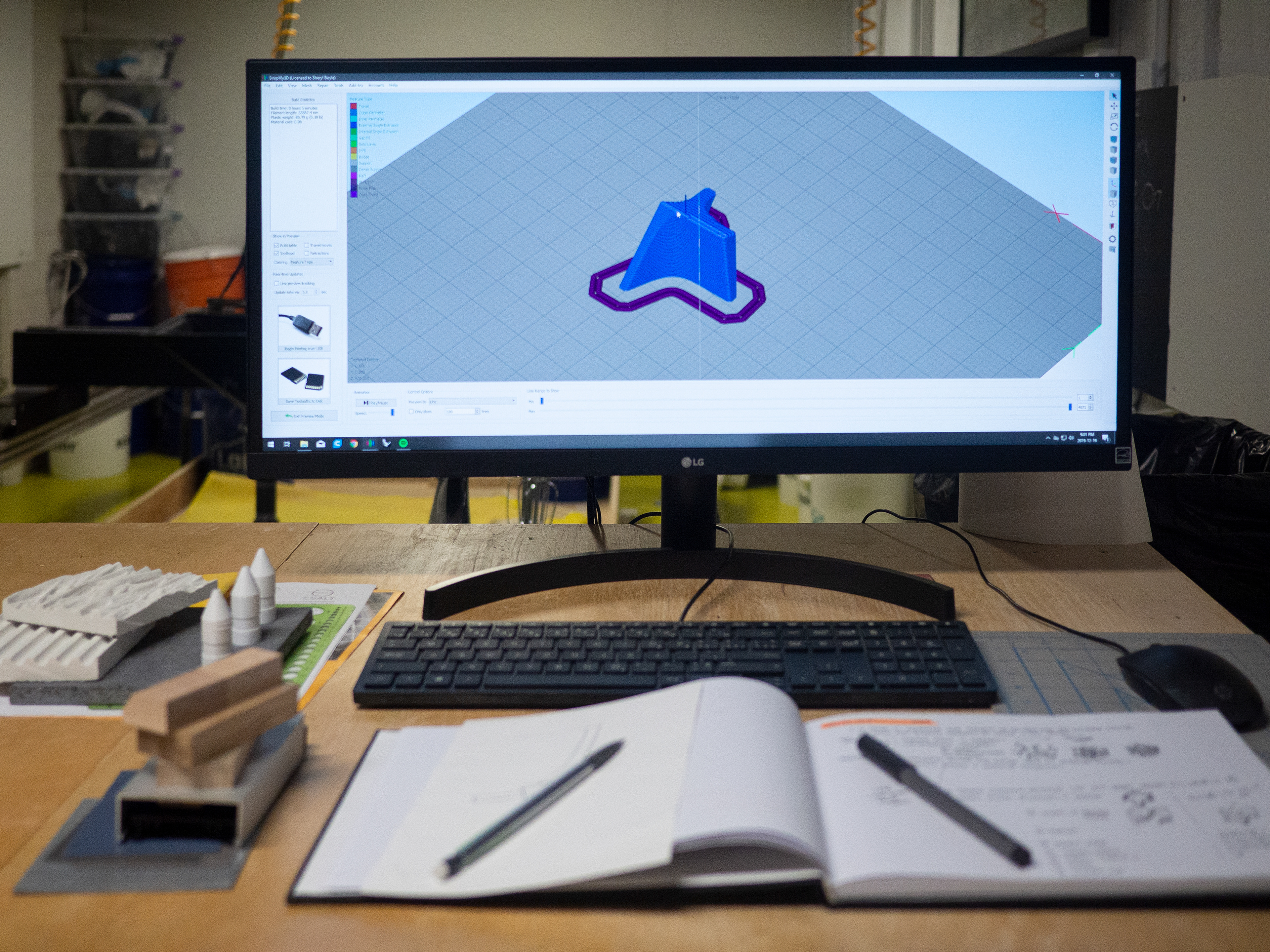

The designs were first tested with an FDM printer to ensure that they could print without support material.

A 3D clay printer was used to estimate the tool path and material behaviour of a concrete 3D printer before moving to the full-scale machine. My first attempt revealed a need to adjust nozzle diameter with wall thickness, material consistency, size, and form. Unfortunately, the pandemic brought my explorations to a halt before the end of my placement.

Thank you to Sheryl Boyle and the CSALT team for allowing me to be a part of this new chapter at Carleton's School of Architecture.